| Angle | ||||

| 0° | 460 | 460 | 460x460 | 460x460 |

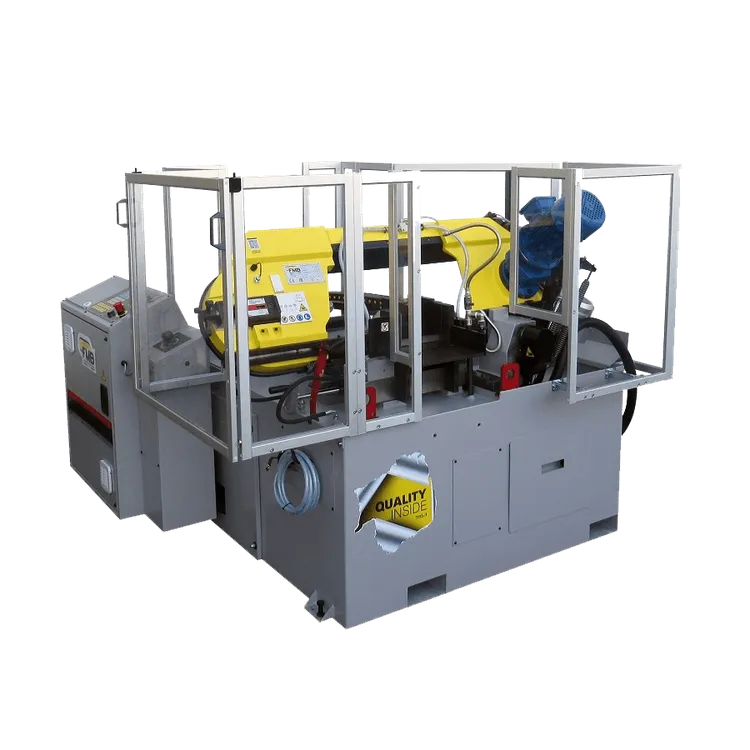

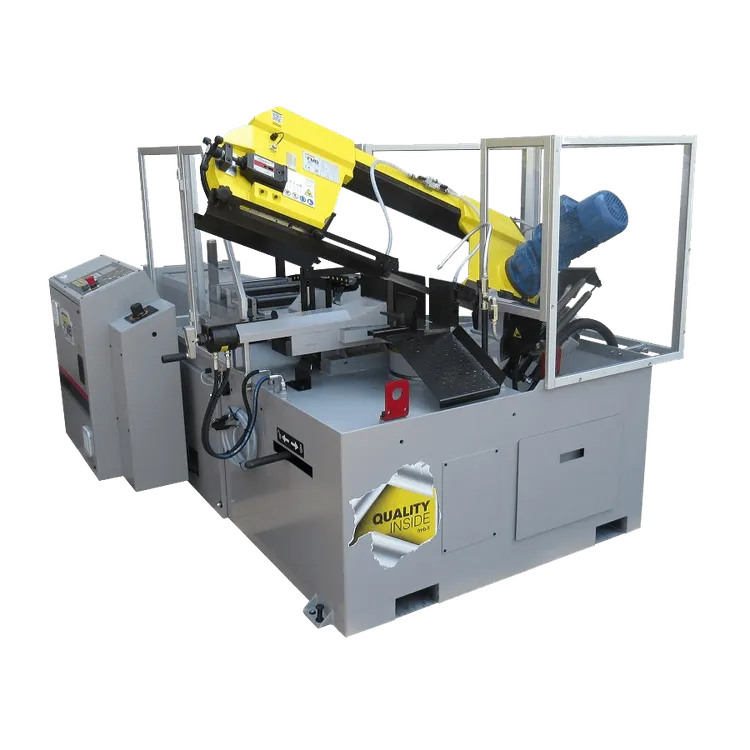

- AUTOMATIC DOUBLE COLUMN BANDSAW MACHINE FOR CUTTING AT 0° WITH DIMENSIONS UP TO 460x460 mm.

- The machine is completely guarded, with an easy access for blade changing and ordinary maintenance.

- Possibility to load material directly on the carriage by bridge crane.

- Standard screw chips conveyor, which can be assembled either on the right or on the left side of the machine.

- 500 mm long feeding carriage stroke with supporting structure, controlled by recirculating screw and encoder.

- Standard hydraulic blade stretching by manual selector.

- The shortest cutting length possible is 8 mm.

- Shortest length of residual piece (scrap) 75 mm.

- Carriage vice and cutting vice equipped with full-stroke cylinders.

- LED working area lighting.

- Wide 180 l tank for the cutting liquid with double water pump and 6 refrigerating utilities.

- Head descent on double column with hydraulic cylinder and and linear guides controlled by SW

- Automatic positioning movable blade-guide frame.

- Carriage vice with moving back fixed jaw, to allow the processing of crooked bars.

- Motorized blade-cleaning brush with a specific nozzle for its lubrication and cleaning with coolant liquid.

- Mechanical device for material presence detection on the feeding carriage.

- Blade speed control sensor.

- Possibility to make interrupted cuts. The interrupted cut value can be changed and be different also in the same cycle.

- Vertical vices option (MV-A) which does not involve any reduction in cutting capacity.With this option the shortest cutting length possible is 25mm.

- The carriage moves back at the end of the cut in order to avoid damages on the blade, this can be set up through the control panel.

Possibility to choose the inclination of the blade in phase of order:

- Athena 41A: 0°- Athena 41A I: 1,5° (specific for rectangular and square sections)

- Totally freeworking area for the best extraction of the chips.

- Maximum protection against high voltage and short circuit.

- Protection level IP 55.

- Line voltage: 400V/50Hz/3Ph standard

- Others available: 230V/50Hz/3P -220V/60Hz/3Ph - 440V/60Hz/3Ph.

- Machine colors: yellow RAL 1018 and grey RAL 7016

- 10" touch screen control panel, with modern and user-friendly interface.

- Multilanguage software.

- 19 families of materials already inserted and possibility to insert customized materials.

- Automatic machines adaptation to the correct cutting parameters depending on the set material and dimensions.

- Possibility to safe until 90 programs.

- Always available daily, weekly statistics, partial and total values.

- Counter of the actual blade cuts.

- Length, pieces number and value of interrupted cut are always changeable in real time during the cycle in execution.

- The machine suggests the correct toothpitch of the blade to be used for the set material and the cutting speed is self-adapting depending on the effective one.

- Swarf extractor which can be temporized.

- Fast approach with laser.

- Remote assistance with the option MT-A.

No videos found. Please check back soon!

No downloads yet. Please check back soon!