Laser Beam - Focus Position

01/01/2023

Laser Beam Focus Position

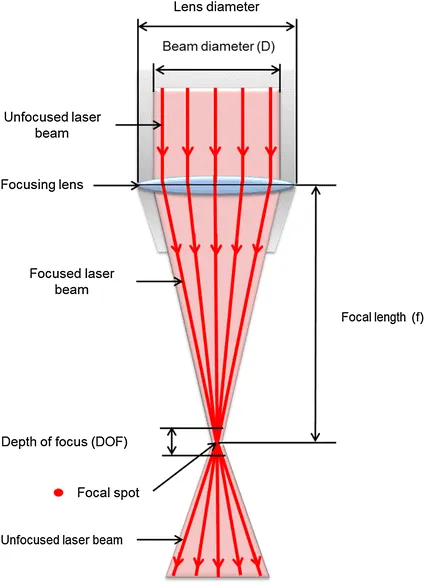

The Fibre Laser Beam focus position, is the distance between the Coherent Monochromatic photon Laser beams focus onto the material to be cut.

A focus position on the material surface is described as a zero focus, during zero focus cutting, the smallest spot size can be obtained on the material surface. This results in a relatively narrow melting range and a smaller cut, making it suitable for high precision Fibre Laser cutting of thin materials

A focus position above the plate is described as a positive focus,

When the Fibre Laser beam focus is positioned above the material, the light beam will spread out and diffuse in the cutting Kerf after reaching the material surface. This will cause the lower part of the cut to be larger than the upper part.

A Fibre Laser Beam focus position below the material is described as a negative focus.

Negative focus cutting involves positioning the Fibre Laser beam’s focus inside the material, thereby ensuring that the lower part of the cut has sufficient energy density. The cut is wider at the top and narrower at the bottom

Focal Length – Guide Line:

A guide line is that when cutting up to 6 mm the focal point, i.e., the spot, should be concentrated on the top of the material, a Zero Focus

For cutting 8 mm and above, the Fibre Laser Beam focal point, i.e., the laser spot needs to be above the material

a Positive Focus

For Stainless Steel and Aluminium, the Fibre Laser Beam focal point i.e., the spot, needs to be two thirds into the material,

a Negative focus

Focal Length

Swiss Raytools Standard Cutting heads, Models BM110 & BM06K,

i.e., without ZOOM functionality, offer 2 standard focal point lengths

i) 100 mm for thin materials, 0-3mm.

ii) 155 m for thicker materials, 4mm-20mm.