| Angle | ||||

| 0° | 330 | 330 | 330x510 | 330x510 |

| ⬅45° | 330 | 330 | 150x430 | 330x330 |

| ⬅60° | 240 | 200 | 120x280 | 330x130 |

| 45°➡ | 330 | 330 | 190x360 | 330x400 |

| 60°➡ | 280 | 240 | 240x270 | 240x270 |

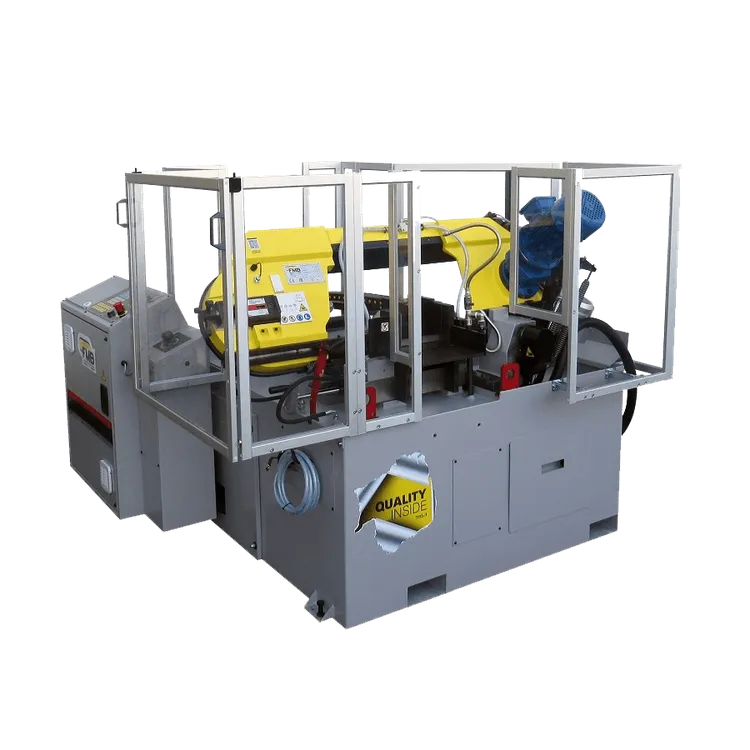

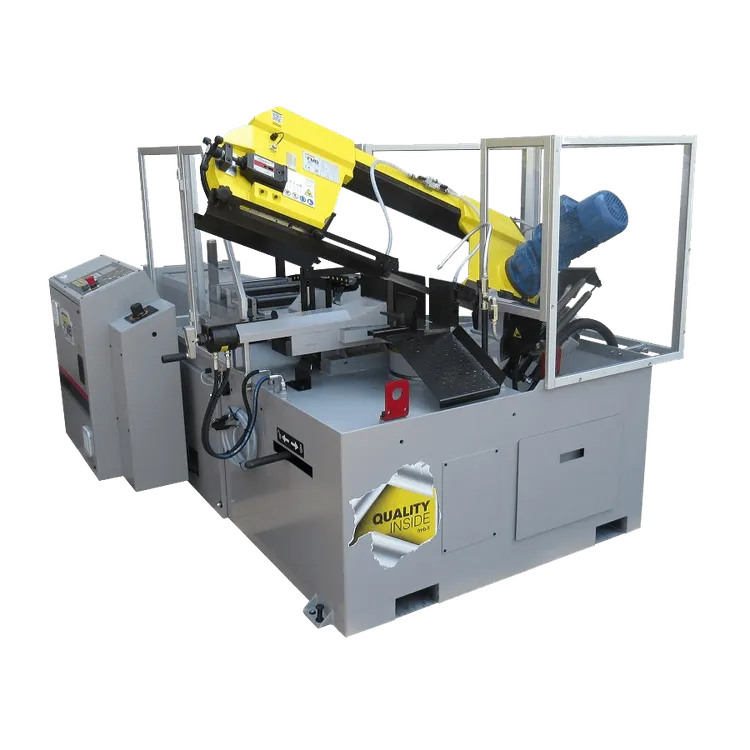

- Semi-automatic bandsaw machine to cut from 0° to 60° right, from 0° to 45° left and up to 60° for trim cut.

- Head structure in 3 parts: special aluminium alloy, steel and cast iron.

- Head feeding system with hydraulic cylinder and front balanced valve for feeding regulation and cutting optimizing.

- Dynamometric blade tensioning.

- Broken blade micro.

- DTI “interrupted cut device” installed as standard equipment.

- Direct drive: Reduction gear box with inclined grinded case hardened teeth lubricated with long lasting grease.

- 16÷120 m/min VHZ electronical blade speed regulation for a wide range of blade speed selection.

- Connection of the motor wheel to a flange with two conical bearings.

- Blade cleaning brush driven by motor gearbox.

- Blade guide with combined action of side bearings, carbide plates and top bearing.

- Material clamping vice with rack system, manual positioning and hydraulic stop cylinder.

- Manual vice translation, right-left, on linear guides with mechanical stops and locking system.

- Ergonomic working table and control panel.

- Head rotation angle stop at 0°, 45° and 60° and digital display for the visualization of the cutting angle and rugged in construction locking lever.

- Two-rolled roller table for material supporting in loading side placed on the basement.

- The roller table as the possibility to slide back so to guaranty material support also during mitre cuts.

- Heavy duty basement. Sheet metal construction in different thickness, chips holding sides.

- Hydraulic cooling pump with 80 l capacity located in the back of the basement for feeding both blade guides.

- Hydraulic unit for head cylinder movement, vice cylinder.

- Electrical cabinet with 24VAC, lockable main switch and electric drives.

- Total protection against highest voltage and short circuit current. Protection level IP 55.

- Push buttons control panel to cary out all machine movements and detect possible alarms.

- Line voltage: 400V/50Hz/3Ph standard (230V/50Hz/1Ph-230V/50Hz/3Ph-220V/60Hz/1Ph-220V/60Hz/3Ph-440V/60Hz/3Ph-575V/60Hz/3Ph available).

- Machine colours: yellow RAL 1018 and grey RAL 7036.

No videos found. Please check back soon!

No downloads yet. Please check back soon!