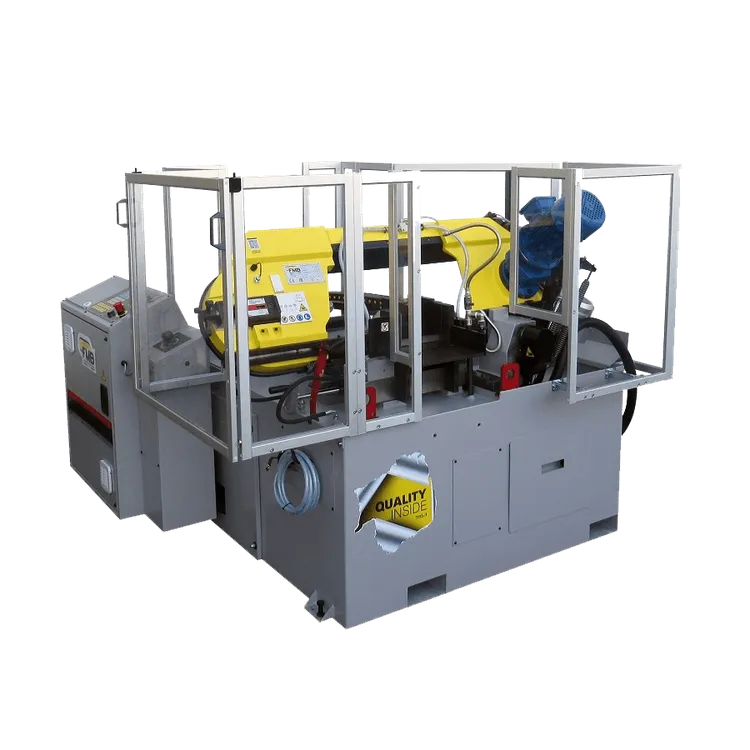

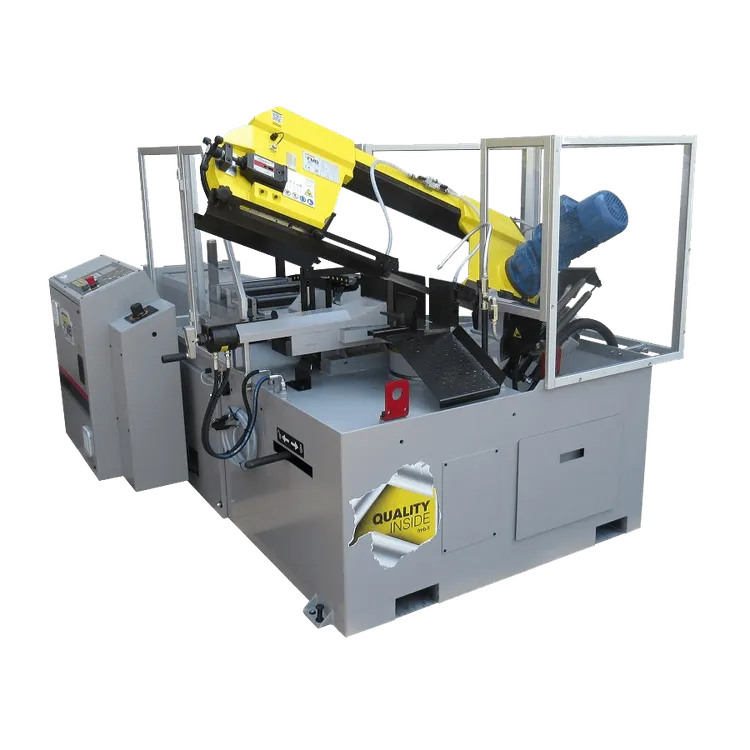

Techna-Fab S200-R Semi-Automatic Bandsaw Features high Fidelity metal cutting, even at 45º/60º. The extremely strong, reliable and simple semi-automatic band saw for metal cutting with automatic lifting and lowering of the arm and a manual vice allowing for easy operator use.

The band saw arm rotates in both directions from -45º to + 60º. This bandsaw can be used for a wide range of cutting applications from cutting pipes, profiles and solid materials. The Techna-Fab S-200R Bandsaw is equipped as standard with automatic lowering and lifting of the arm as well as a height adjuster allowing the arm to be raised to a height suitable for the material to be cut allowing for maximum efficiency while cutting. Thanks to the automatic hydraulic cylinder, the manual operation of the machine has been simplified to feed and clamp the material to be cut in a vice.

The arm made of cast iron together with a refined stable structure provides the Tchna-Fab S-200R saw with exceptional stiffness which translates into trouble-free operation and very high cutting precision. Innovation and production of Techna-Fab power bandsaws of semi-automatic according to standards and standards-compliant with ISO: 90001 and ISO: 140001 certificates, guarantees safety, quality and product reliability. The use of "M3V" series motors from a well-known and respected global manufacturer Of high-quality motors, one of the world leaders, ABB company guarantees long and trouble-free operation.

Machine operator starts the machine by pressing the START button and sets the cutting speed. After the cycle is finished the machine automatically stops and the machine lifts the arm to the starting position. This model can be used in both low and high quantity production, and its solid construction allows for cutting various materials, including stainless steel, tool steel and profiles. The machine provides cutting at an angle due to the rotary arm. The band saw arm is made of uniform cast iron, and together with 27mm wide blade enables high quantity cutting of various materials.

The vice is equipped with a quick clamp. Blade guides are equipped with a ball bearings system and cemented carbides, ensuring excellent cutting precision and straight cut. The arm is equipped with an automatic blade tension sensor, at a 25° angle, thus increasing the blade's durability. There is a blade cleaning brush attached to the bottom of the arm. The machine drive is transmitted through a worm drive filled with gear oil. The machine is equipped with a three-phase motor with double winding and two cutting speeds. The motor is thermally protected.

Two cutting band speeds: 35 and 70 m/min. Technical Data Type: Semi-Automatic Raising and lowering of arm: Hydraulic with smooth adjustment of the lowering of the arm Band speed: 35/70 mm / min Cutting for angles: Left from 45 ° to 60 ° right Vice: Manual Minimum cutting diameter: Ø 5 mm Minimum length of material in a vice: 30 mm Height of the vice base: 780 mm Blade size: 27 x 0.9 x 2910 mm Total power: 2.1 kW Machine Dimensions (L x W x H): 1600 x 800 x 1400 mm Weight: 530 kg Standard equipment • Control console on a separate pedestal • Built-in hydraulic unit • Hydraulic control of arm movement (up-down) with the possibility of smooth regulation of falling speed to allow cutting of different materials • Arm position memory function (return of the arm after cutting to a specific height) • Cutting at an angle of L / R 45 ° - 0 ° - 45 ° - 60 ° • Brush cleaning the blade • Cooling system • Bi-metal band saw blade • Declaration of conformity CE • Technical and Movement Documentation